Pure Water at a Low Cost

Large capacity RO system for boiler feedwater Click here for pre-treatment/post-treatment equipment

Reverse osmosis is the most efficient process available to remove dissolved minerals, bacteria, particles and organic impurities from water supplies. Pre-engineered and custom designed Reverse Osmosis systems produce high-purity water economically for a variety of commercial and industrial applications including:

- Food and Beverage

- Municipal water treatment systems

- Chemical processing

- Laboratory applications

- Boiler feed water

- Metal finishing

Our RO systems are constructed for reliable, trouble-free operation using only the finest materials and components available.

Features

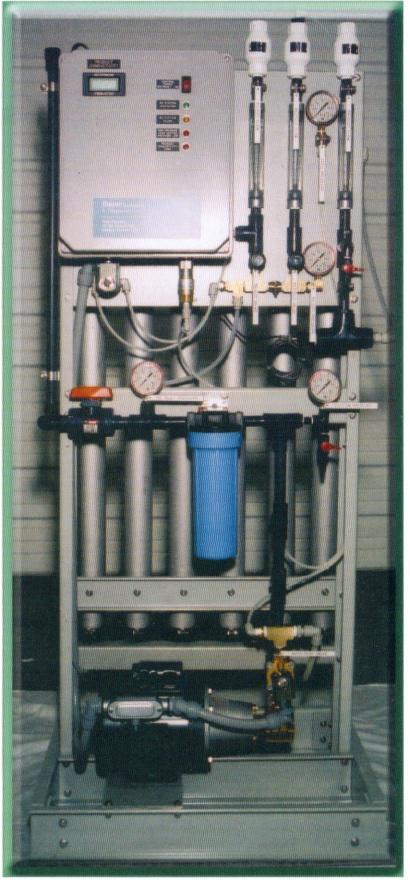

Small capacity Reverse Osmosis

- Fiberglass frame

- Stainless multistage centrifugal pumps

- Spiral wound, thin film composite membranes

- Cartridge pre-filter

- Systems are pre-assembled and factory tested

- Control panel - NEMA 4 control panels include digital conductivity monitor, programmable controller, tank level control, fuses, motor starter, switches and control transformer

- Control valves - pump and reject throttle valves are included for flow and pressure control.

- Automatic flush reduces corrosion potential and membrane fouling.

- Liquid-filled pressure gauges assure pulse-free readings and long gauge life.

- Line-mounted flow meters offer consistent accuracy and corrosion-free performance.

- Convenient layout - all gauges, meters and controls are located next to the control panel for ease of operation.

- Feedwater control valve automatically shuts off feedwater when system is not operating.

- Low pressure switch protects the pump from damage caused by inadequate pump inlet pressure.

Options and Accessories

Ultra low pressure membranes - reduce power consumption by 30% or more.

Membranes - alternate membranes including nano filtration, seawater, cellulose acetate and softening membranes are available.

Two-pass RO - produces ultra pure water at low cost.

Pre-treatment equipment - filters, softeners, chemical feed systems, UV sterilizers, ultra-filtration and micro-filtration systems are all available to prevent scaling and fouling of the RO membranes.

Post-treatment equipment - degasifiers, chemical feed systems and UV sterilizers are provided to assure that the product water is within specifications.

Deionizers - polish the RO product water to meet applicationĀ specifications including ultra-pure water.

Specifications - Small Capacity Reverse Osmosis Systems

| Model |

Capacity (gpd) Maximum / Typical |

Conversion % |

Motor HP |

Membrane Size (Qty) |

Dimensions L x W x H (in.) |

Connections (in.) Feed Permeate Conc. |

| LS-275 |

260 / 210 |

50 |

1/3 |

2.5" x 21" (1) |

32 x 16 x 32 |

1/2" 1/2" 1/2" |

| LS-550 |

520 / 420 |

50 |

1/3 |

2.5" x 21" (2) |

32 x 16 x 32 |

1/2" 1/2" 1/2" |

| LS-825 |

780 / 630 |

50 |

1/3 |

2.5" x 21" (3) |

32 x 16 x 32 |

1/2" 1/2" 1/2" |

| LS-1200 |

1120 / 900 |

50 |

3/4 |

2.5" x 40" (2) |

28 x 22 x 60 |

1/2" 1/2" 1/2" |

| LS-1800 |

1680 / 1350 |

50 |

3/4 |

2.5" x 40" (3) |

28 x 22 x 60 |

1/2" 1/2" 1/2" |

| LS-1800 |

1680 / 1350 |

50 |

3/4 |

2.5" x 40" (4) |

28 x 22 x 60 |

1/2" 1/2" 1/2" |

| LTF 1-3800 |

3480 / 2780 |

65 |

3 |

4.0" x 40" (2) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1-5700 |

5220 / 4170 |

65 |

3 |

4.0" x 40" (3) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1-7600 |

6960 / 5560 |

65 |

3 |

4.0" x 40" (4) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF1-9500 |

8700 / 6950 |

65 |

3 |

4.0" x 40" (5) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1-11400 |

10440 / 8340 |

65 |

3 |

4.0" x 40" (6) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1H-3800 |

3220 / 2560 |

65 |

5 |

4.0" x 40" (2) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1H-5700 |

4830 / 3840 |

65 |

5 |

4.0" x 40" (3) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1H-7600 |

6440 / 5120 |

65 |

5 |

4.0" x 40" (4) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1H-9500 |

8050 / 6400 |

65 |

5 |

4.0" x 40" (5) |

54 x 30 x 70 |

1" 3/4" 3/4" |

| LTF 1H-11400 |

9660 / 7680 |

65 |

5 |

4.0" x 40" (6) |

54 x 30 x 70 |

1" 3/4" 3/4" |

- Typical system capacity is after 3 years of operation at standard conditions with 50 deg F or warmer water. Maximum capacity requires ideal operating conditions.

- Standard operating conditions are 1000 ppm TDS softened feedwater, SDI less than 3.0, 50 to 65% conversion.

- The LS series units require 115VAC single phase 60Hz power. The LTF1 and LTF1H series require 208-230/460 VAC 3 phase, 60Hz power. Alternate voltages are available.

- Detailed specifications, drawings and computer projections are available on request.

Specifications - Small Capacity Reverse Osmosis Systems

| Model |

Capacity (gpd) Maximum / Typical |

Motor HP |

Dimensions L x W x H (in.) |

Connections (in.) Feed Permeate Conc. |

| LTF2-14400 |

14,040 / 12,540 |

5 |

135 x 38 x 70 |

1 1/2" 1" 1" |

| LTF2-19200 |

18,690 / 16,700 |

7.5 |

135 x 38 x 70 |

1 1/2" 1" 1" |

| LTF2-24000 |

23,370 / 20,900 |

7.5 |

135 x 38 x 70 |

1 1/2" 1" 1" |

| LTF2-28800 |

28,040 / 25,000 |

10 |

135 x 38 x 70 |

1 1/2" 1" 1" |

| LTF3-42000 |

41,600 / 35,040 |

15 |

145 x 36 x 80 |

2" 1 1/2" 1" |

| LTF3-63000 |

62,400 / 52,560 |

15 |

145 x 36 x 80 |

2" 1 1/2" 1" |

| LTF3-84000 |

83,220 / 70,080 |

20 |

145 x 36 x 80 |

2" 2" 1 1/2" |

| LTF3-105000 |

104,020 / 87,600 |

25 |

145 x 50 x 80 |

2 1/2" 2" 1 1/2" |

| LTF3-126000 |

124,800 / 105,100 |

30 |

145 x 50 x 80 |

2 1/2" 2" 1 1/2" |

| LTF4-112000 |

110,900 / 93,400 |

30 |

192 x 50 x 80 |

2 1/2" 2" 1 1/2" |

| LTF4-140000 |

138,700 / 116,800 |

30 |

192 x 50 x 80 |

3" 2 1/2" 2 1/2" |

| LTF4-168000 |

166,440 / 140,160 |

40 |

192 x 50 x 80 |

3" 2 1/2" 2 1/2" |

| LTF4-210000 |

208,100 / 175,200 |

50 |

272 x 50 x 80 |

4" 3" 3" |

| LTF4-252000 |

250,000 / 210,240 |

50 |

272 x 50 x 80 |

4" 3" 3" |

- Typical system capacity is after 3 years of operation at standard conditions with 55°F or warmer water. Maximum capacity requires ideal operating conditions and high area membranes.

- Standard operating conditions are 1000 ppm TDS softened feedwater, SDI less than 3.0, 70 to 80% conversion, 50 PSI inlet.

- Detailed specifications, drawings and computer projections are available on request.

- Standard power is 460 VAC, 3Ų, 60 Hz.

For more information, including pricing, please contact Continental Hydrodyne Systems.

|

|